- Toothbrush Tufting Machine

- Blister Packaging Machine

- Plastic Mould

- Toothbrush Hot Foil Stamping Machine

- Toothbrush Filament Cutting Machine

- Toothbrush Trimming Machine

- Toothbrush Tufting & trimming Machine

- Toothbrush Machine Robot Manipulator

- High Frequency Packing Machine

- Eyebrow Brushing Machine

- Injection Molding Machine

High Frequency Welding Machine For Tooth Brush

Brand: Chuangyan

Product origin: Guangdong

1. The main oscillation circuit adopts distributed parametric cavity and well-designed high-frequency transmission tuning system to make its oscillation stable, high efficiency, uniform heating, strong load capacity, complete and reliable control protection.

2. The resonant cavity is unique in design, with high quality factor, reasonable structure, high electromagnetic conversion rate, good frequency stability, and meets the international CISFR standard requirements, which is easy to match with the load.

3. The main high-frequency tube adopts high-frequency medium heating equipment oscillator special tube 8T85RB. The tube has the advantages of small volume, high power, long life, and low energy consumption.

4. The mechanical transmission design is reasonable and perfect, the head is stable up and down, the pressure is adjustable, and the trolley is stable and accurate.

5. It has complete functions, simple and convenient operation, and is widely used. It is an ideal medium heating device.

Note: The service life of the high-voltage AC contactor is 500,000 times. When the service life exceeds the service life, the contact is easy to stick to damage the equipment. Therefore, the device adds a protective measure: when the contact is stuck, the voltage of the tube filament is cut off and the voltmeter The indication is zero. (The touch screen is still displayed)

High Frequency Heat-sealing Machine

Production Specifications:

| SPECIFICATIONS | |||

| Power | three-phase 380V 50Hz | Cooling method | air cooling |

| Power consumption | 30KVA | Rectifier | three-phase bridge |

| High frequency output power | 15KW | Protection device | spark protector, over current protector |

| Electric heating board power | 2.7KW | Pressure source | cylinder |

| Oscillation frequency | 27.12MHz | One pressurizing pressure | 700Kg (adjustable) |

| Swing tube | 8T85RB | Secondary pressurization pressure | 20000Kg (adjustable) |

| Upper plate size | 400 × 550 mm² | Lower plate size: | 480×600 mm² |

| Heat sealing thickness | 0.1~2mm | Left (right ) heat sealing time | 0 ~ 9.9 s |

| Left (right ) cooling time | 0 ~ 9.9 s | Left (right ) cut-off time | 0 to 9.9 s |

| Left (right ) delay | 0 ~ 1.5 s | Operation mode | double station, fully |

| Dimensions | 2200 × 1280 × 2100㎜³ | Machine weight | 1.6 tons |

Details Images:

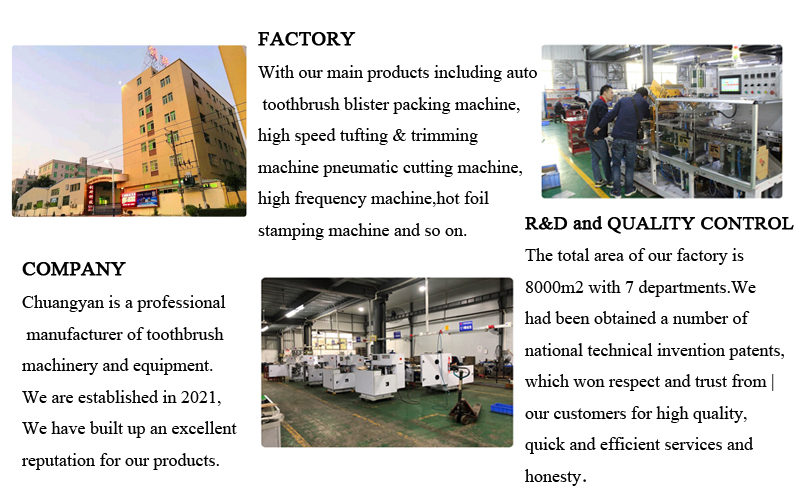

Company Introduction:

Certificate Display:

Our Partners:

Exhibition:

Packing & Delivery:

| Packaging | |

| Size | 2200 × 1280 × 2100㎜³ |

| Weight | 1.6 tons |

| Packaging Details | The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

FAQ: