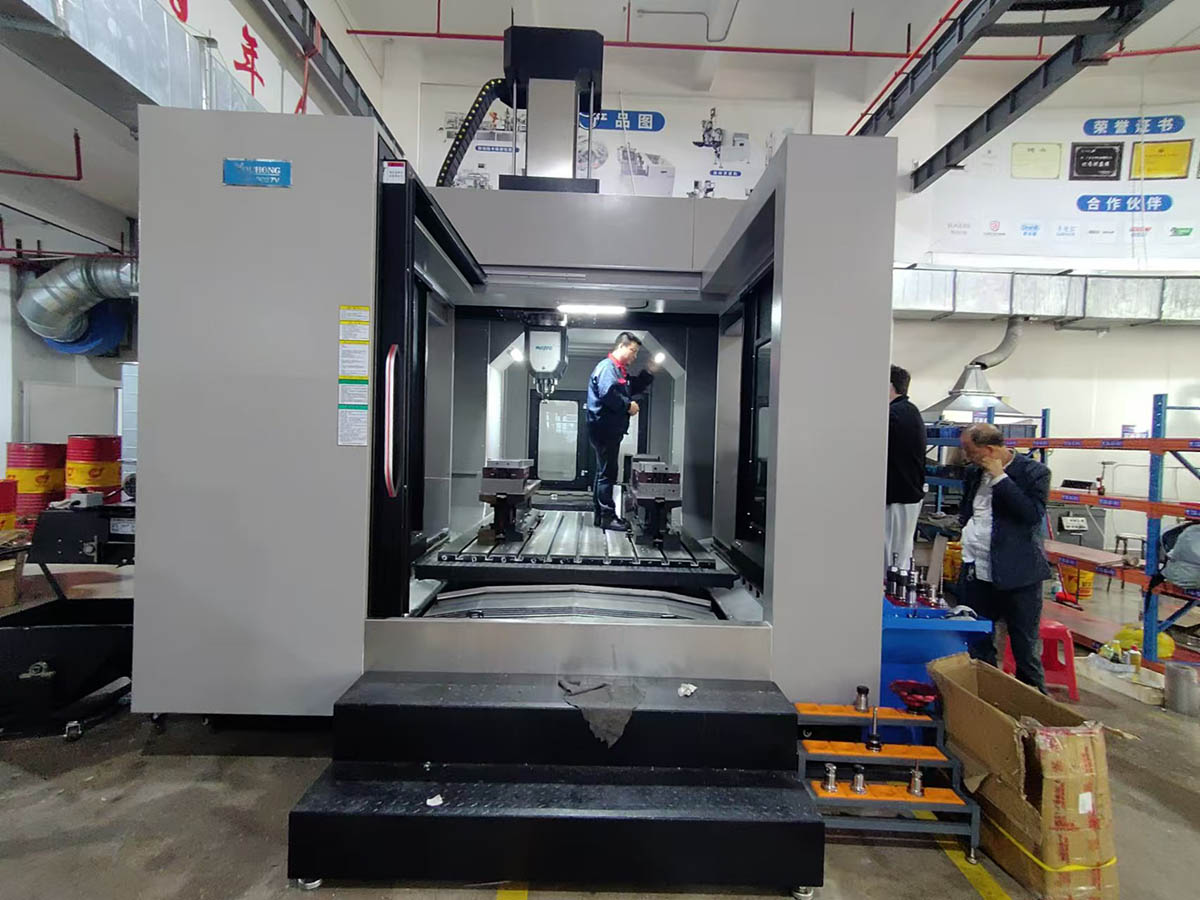

Introducing Our New Five-Axis Gantry Machining Center

At Guangdong Chuangyan Technology Co., Ltd., a leading manufacturer of toothbrush machinery, we are constantly innovating to deliver advanced solutions to our clients worldwide. In line with this commitment, we are excited to introduce our new Five-Axis Gantry Machining Center. This upgrade enhances our manufacturing capabilities and underscores our dedication to precision engineering.

What Is a Five-Axis Gantry Machining Center?

A Five-Axis Gantry Machining Center is a machine tool designed for complex and precise tasks. Unlike traditional three-axis machines, which move in three linear directions (X, Y, Z), a five-axis machine adds two rotational axes (A, B). This capability allows processing of intricate parts with exceptional accuracy and efficiency.

The gantry structure ensures superior stability, making it ideal for handling large and heavy components. Its ability to work on multiple angles in a single setup significantly reduces production time and improves product quality.

Key Features of Our New Machine

1. Gantry Structure

High Stability: The gantry-style machine is composed of two vertical columns and a crossbeam, forming a stable frame structure suitable for machining large workpieces.

Large Machining Range: The gantry structure provides a spacious working area, accommodating larger or longer workpieces.

2. Five-Axis Linkage

Three Linear Axes (X, Y, Z): Responsible for linear motion.

Two Rotational Axes (A, C or B, C): Adjust the tool's angle for machining complex surfaces.

High Freedom: Five-axis linkage allows the tool to approach the workpiece from multiple angles, reducing the need for multiple setups and improving precision and efficiency.

3. Key Advantages

Complex Surface Machining: Capable of handling tasks like aerospace engine blades and molds that are beyond the capabilities of traditional three-axis machines.

High Efficiency and Precision: Reduces errors caused by multiple setups, significantly improving accuracy.

Broad Applicability: Suitable for machining metals, composites, and other materials.

4. Typical Applications

Aerospace: Manufacturing aircraft components and high-precision engine turbine blades.

Automotive Manufacturing: Producing complex car body molds and high-performance parts.

Energy Sector: Machining wind turbine blade molds and hydroelectric turbines.

Why This Upgrade Matters?

The Five-Axis Gantry Machining Center benefits both our company and our customers by:

Improving Product Quality: Ensuring components meet or exceed industry standards.

Reducing Lead Times: Streamlining processes for faster delivery.

Expanding Capabilities: Supporting the production of complex and customized parts.

Promoting Sustainability: Minimizing material waste and energy use.

Applications in Toothbrush Machinery Manufacturing

The toothbrush industry requires high precision, particularly for molds, holders, and bristle tufting modules. This machining center enables us to:

Manufacture intricate molds with ergonomic designs and quality finishes.

Produce durable jigs and fixtures for assembly and tufting.

Create specialized components tailored to customer needs.

Commitment to Innovation

At Guangdong Chuangyan Technology Co., Ltd., we continuously invest in technology and innovation. This advanced machining center reflects our dedication to providing world-class products and services.

Partner with Us

With this new addition to our production line, we are better equipped to meet the diverse needs of our global clients. Whether you need standard machinery or customized solutions, we deliver exceptional results.

If you're interested in learning more, please contact us. Let's work together to elevate your toothbrush manufacturing processes.

Thank you for choosing Guangdong Chuangyan Technology Co., Ltd.as your trusted partner. We look forward to building a successful future together.