- Toothbrush Tufting Machine

- Blister Packaging Machine

- Plastic Mould

- Toothbrush Hot Foil Stamping Machine

- Toothbrush Filament Cutting Machine

- Toothbrush Trimming Machine

- Toothbrush Tufting & trimming Machine

- Toothbrush Machine Robot Manipulator

- High Frequency Packing Machine

- Eyebrow Brushing Machine

- Injection Molding Machine

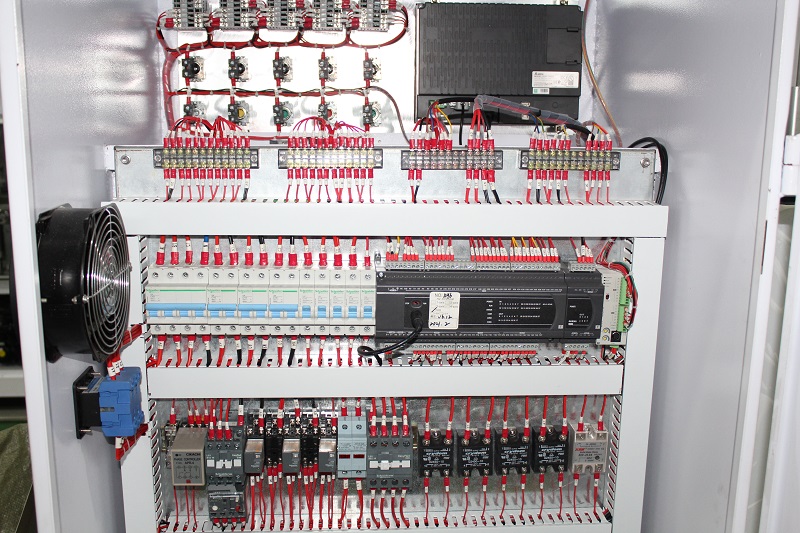

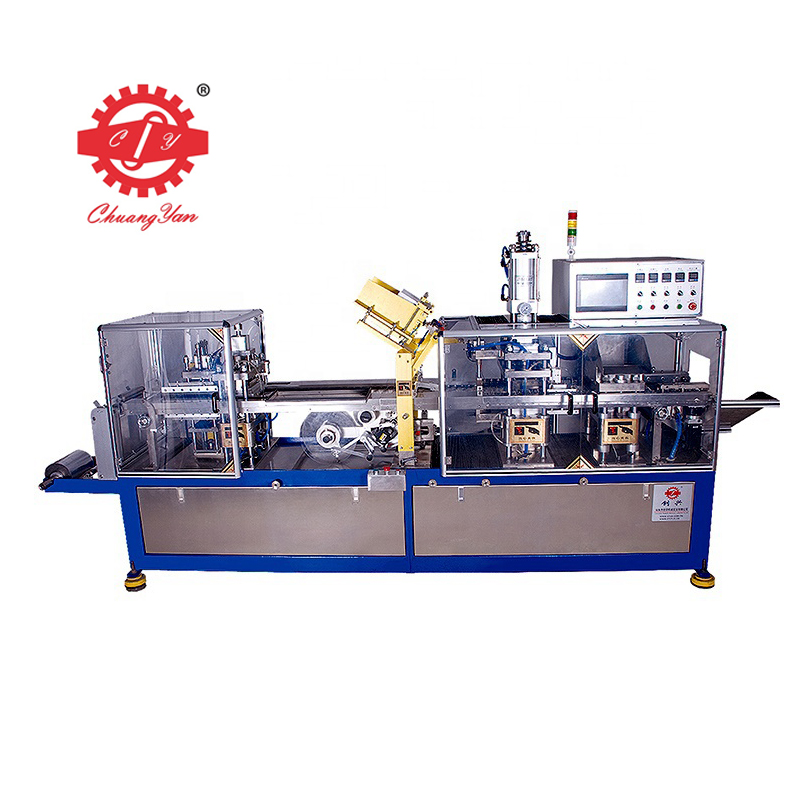

Automatic Blister Packing Machine

Brand: Chuangyan

Product origin: Guangdong

Delivery time: 45 days

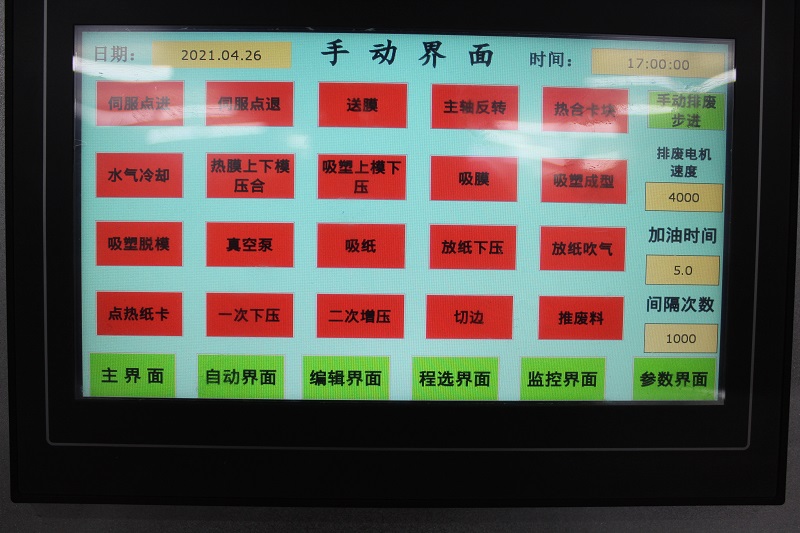

Based on former toothbrush packing technology from Korea Xinya and German our researchers took the initiative to develop a new type of Automatic Toothbrush Blister Labeling & Packing Machine,combining with the new toothbrush in the market.Comprised of automatic paper setting,thermal synthesis technology and punching shear,this machine applies full Servo labeling,enjoying high-tech imported CNC coding and PLC programmable logic ,which gives this new machines an edge in high efficiency,high stability high adjustability,low cost of molding,convenient replacment,low wear,low noise level and so on.

This machine has been obtained a number of nationak technical invention patents.

BZJ-B3 Automatic Blister Packing Machine

Product Specification:

| Specifications | |||

| Model | BZJ-B3 | Capacity | 3000 pcs/hour |

| Pressure | 0.5-0.7 MPa | Mould specification | 3 pieces in one mould |

| Powe | Three-phase four-wire 380V50Hz 5Kw | Packing Material Thickness (PVC/PET) | 0.15-0.5 mm |

| Air consumption | ≥0.15 m2/min | Max Molding Area | 250*180 mm |

| Pressure | 0.5-0.7 MPa | Max Forming Depth | 40 mm |

| Punching Frequency | 15-20 pcs/min | Max Label Length | 80 mm |

| Size | 3850*1100*1800 mm | Weight | 2500 Kg |

| CAPACITY TABLE | ||||||||

| Quantity in 1 package | Mould Specification | Package Width | Work Time (hour) / Capacity (pieces) | |||||

| 13 | 14 | 15 | 16 | 17 | 18 | |||

| 1 pcs | 4 pcs in one | within 42 mm | 37 | 40 | 43 | 46 | 48 | 51 |

| 1-2 pcs | 3 pcs in one | 50-57 mm | 28 | 30 | 32 | 34 | 36 | 38 |

| 2-5 pcs | 4 pcs in one | 58-85 mm | 18 | 20 | 22 | 24 | 26 | 28 |

| 6-10 pcs | 4 pcs in one | 86-150 mm | 90 | 10 | 11 | 12 | 13 | 14 |

Product Detaied:

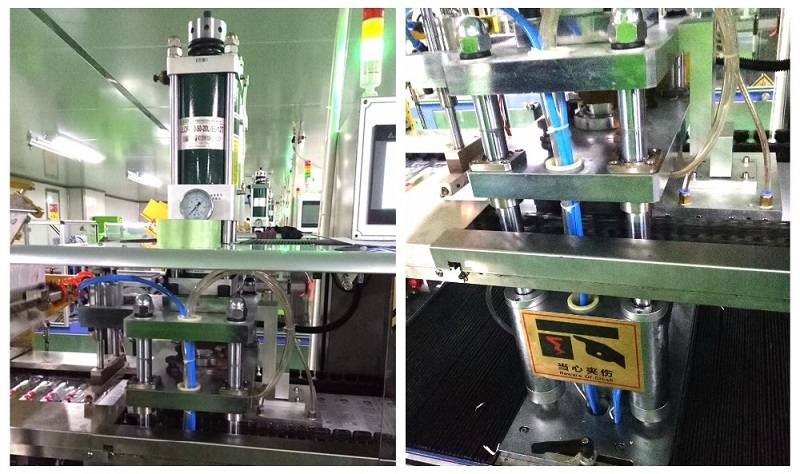

1 Spindle Part

Principle:

Using servo double cam linkage spindle.

Features:

(1) High precision synchronized positioning of dies.

(2) High torque (maximum torque: 40000 kgm)

(3) High stability, low wear and noise.

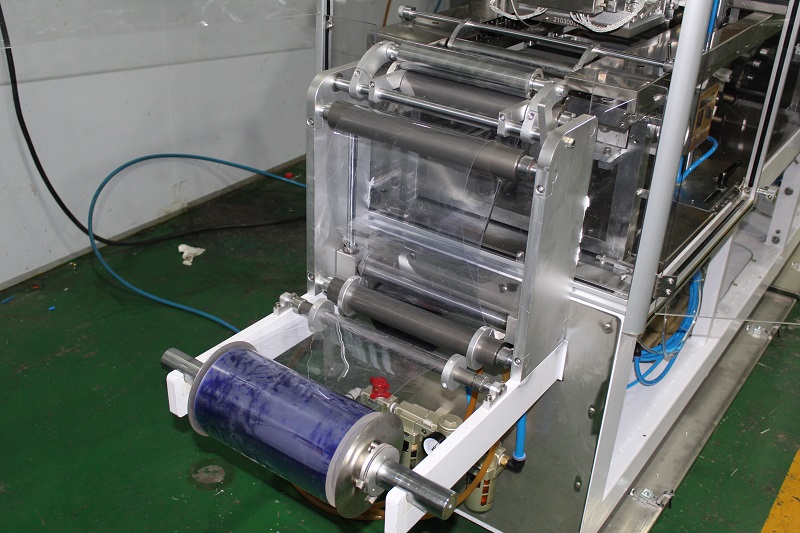

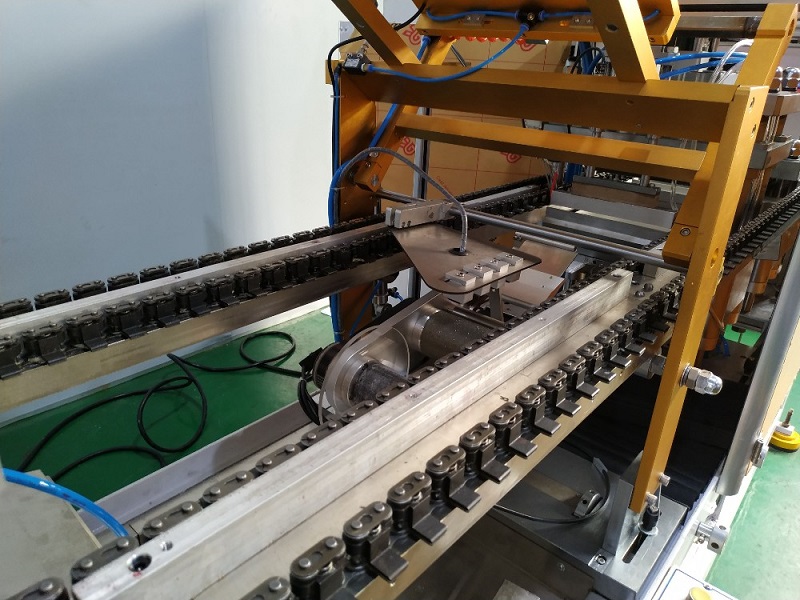

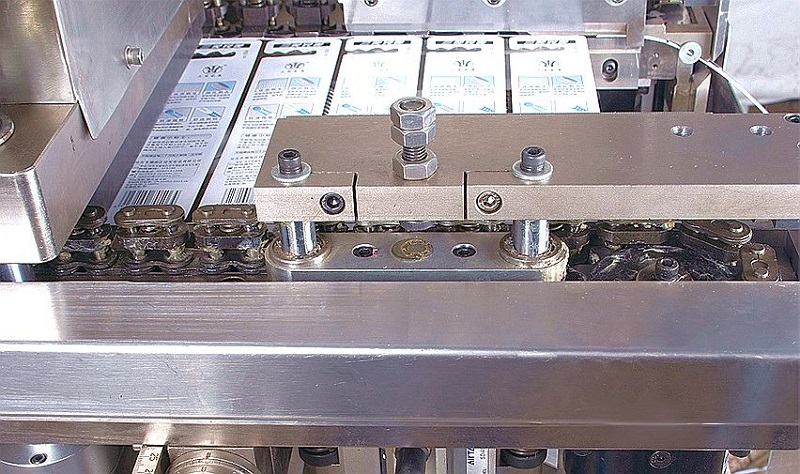

2 Film-drawing Part

Principle:

Using servo drive chain clamp film.

Features:

The film is positioned with a smooth tolerance of ±0.2mm, large adjustable stroke and filming without pasted.

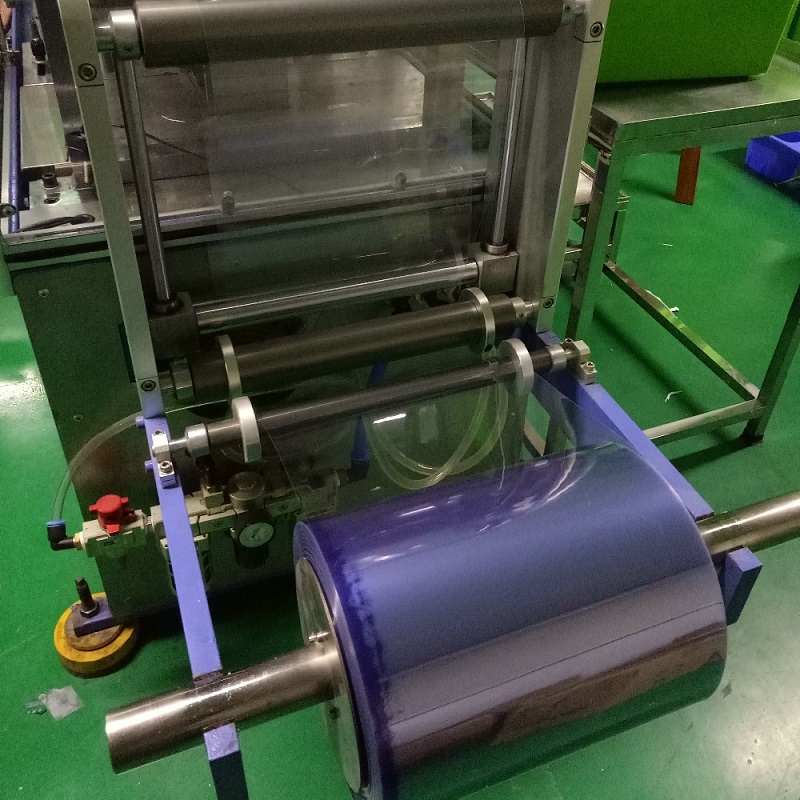

3 Blister Part

Principle:

Using pneumatic slider position

Features:

Precise blister positioning depth, compact structure, low air consumption and easy mold replacement.

4 Heat-sealed Part

Principle:

Using heat sealed and adjustable liquid pressurized cylinder

Features:

Good heat-sealing paste effect, good flatness, high efficiency, strong adjustability of paper card thickness.

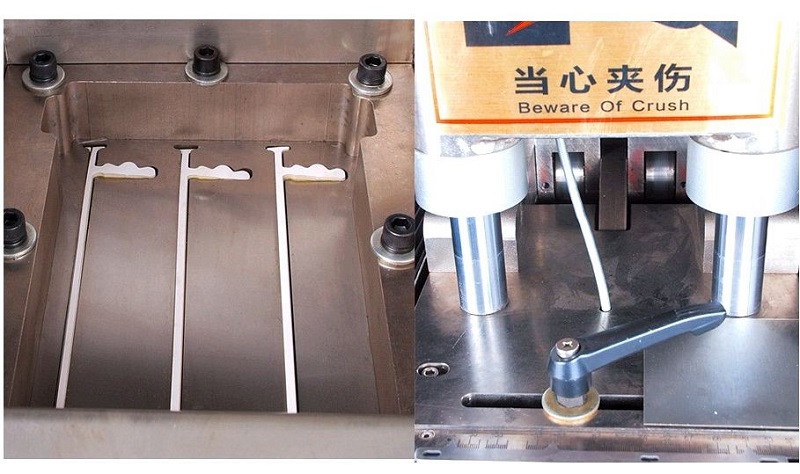

5 Punching part

Principle:

Using double cam with soft cutting and punching.

Features:

Low cost of punching die, easy replacement, small blanking force and low noise.

6 Paper Feeding Part

Principle:

Using special scanning prospecting type.

Features:

(1) High resolution of front and back of the paper card, not cause heat-sealing sticky on the die.

(2) Multi-layer paper card detachable function.

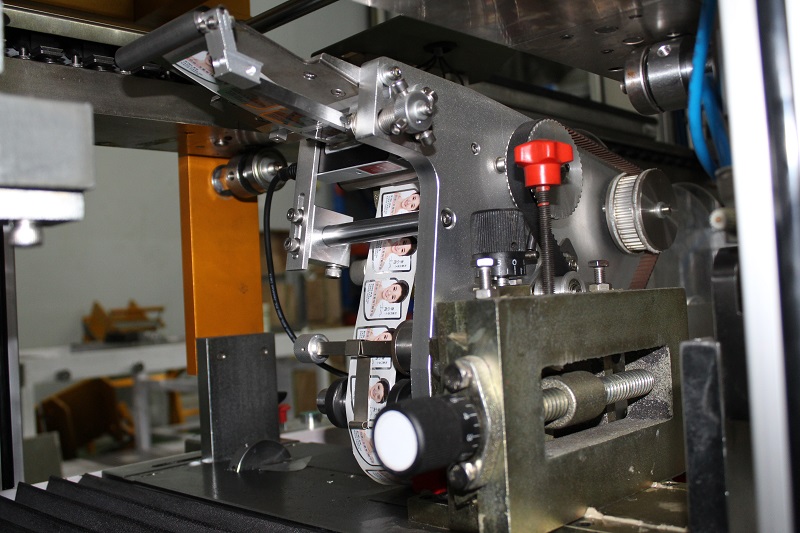

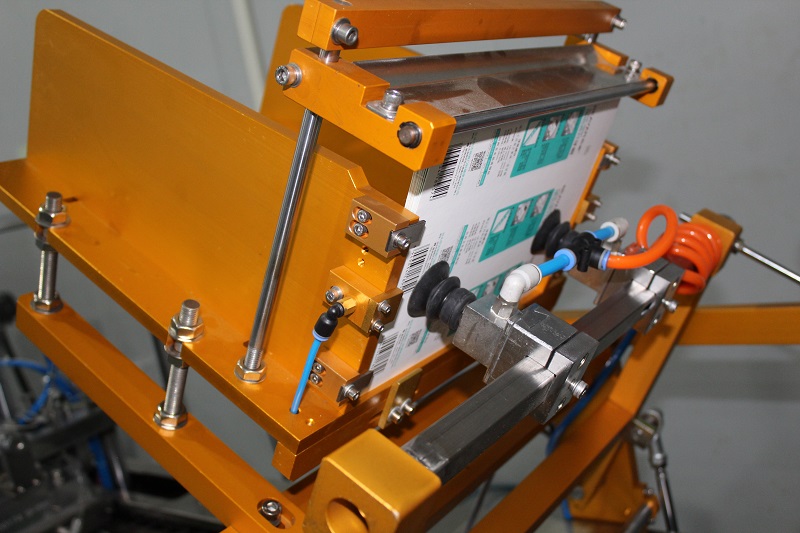

7 Labeling part

Principle:

Using servo drive reverse labeling.

Features:

High smooth accuracy of label positioning, strong adjust ability of three-axis and simple operation of exchanging the label.

8 Trimming and discharging part

Principle:

Using automatic layout of trimming material.

Features:

(1) Simple operation, small space, high production efficiency, low downtime rate, strong adjustability and no manual material removal.

(2) Foundation of matching equipment for automatic plug-in card.

9 Vacuum, Steam and Oil Circuit Parts

Principle:

Using automatic layout of trimming material.

Features:

(1) Simple operation, small space, high production efficiency, low downtime rate, strong adjustability and no manual material removal.

(2) Foundation of matching equipment for automatic plug-in card.

Product Photos:

Our Company:

Exhibition:

Certification: