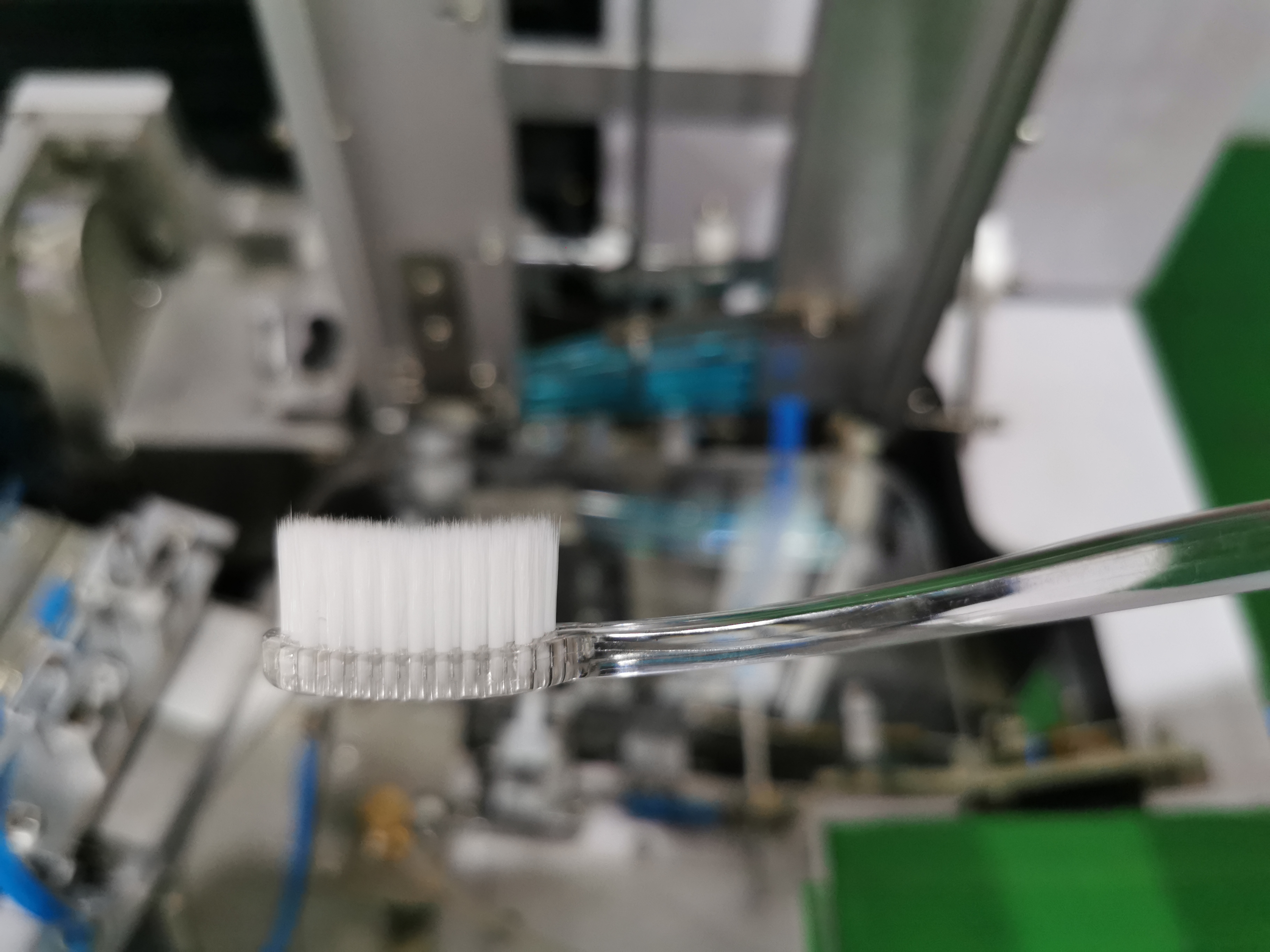

- Toothbrush Tufting Machine

- Blister Packaging Machine

- Plastic Mould

- Toothbrush Hot Foil Stamping Machine

- Toothbrush Filament Cutting Machine

- Toothbrush Trimming Machine

- Toothbrush Tufting & trimming Machine

- Toothbrush Machine Robot Manipulator

- High Frequency Packing Machine

- Eyebrow Brushing Machine

- Injection Molding Machine

Tufting Machine for Bamboo Toothbrush

Brand: Chuangyan

Product origin: Guangdong

Features:

1.R&D automatic intelligent digital control scanning hole coordinate touch screen LCD computer base on German CNC technology.

2.Adopting Japan Fuji 4 axis servo motor.

3.Installing trimming device to reduce trimming process.

4.The whole machine uses German INA,AFG,DURBAL,JAPAN NSK,IKO and other brands of bearings.

5.Universal fixture and universal special-shaped handle box.

6.Automatic cylinder pressure, nylo rolling handle-off hopper.

7.Strong stability of the whole closed loop system,high precision of repeated positioning,easy operating and strong anti-interference ability.

High Speed Intelligent CNC Tufting Machine

Production Specifications:

| SPECIFICATIONS | |||

| Servo motor | Japan's Fuji | Computer | Touch screen LCD |

| Speed | 820 holes/min | Configuration | 3 models (high/middle/low) |

| Power Input | Three-phase 380V AC 2.2KW (MAX) | Filament Box | 2 modes (Double colors/Three colors) |

| Air Source Input | 0.4-0.5MPa | Positioning accuracy | 0.05mm/100mm |

| MEAS | 1250*1250*1450(mm) | Filament length | 10-15mm |

| GW | 900kg | Ordinary circular Aperture | 1.2-3mm |

Details Images

Intelligent NC Computer Parts

Features:

1) The introduction of Germany CNC technology research and development of intelligent numerical control touch screen LCD computer scanning hole coordinates.

2)Used the American import NC CPU chip, speed P4 and dual core.

3)Automatic tracking speed.

4) Positioning precision, convenient operation.

5)The system is stable and reliable, adapted to adapted to different environment.

6) The whole closed loop system, strong anti- interference ability.

7) Can be upgraded to the highest number of flocking 99 holes.(additional options)

8)Can be point to upgrade to add wool implement.(additional options)

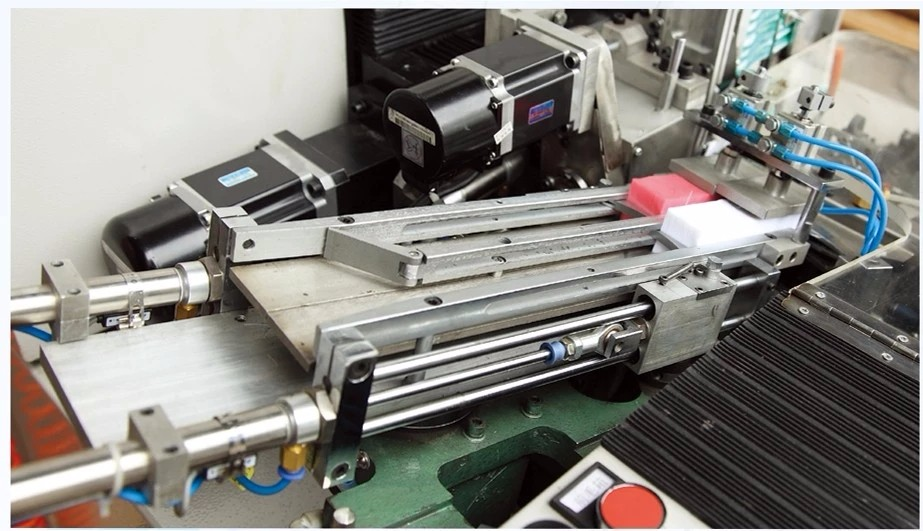

Servo Motor Parts

Features:

1) Adopted original high precision servo motor imported from Japan for the worktable of X axis , Y axis and handle's change.

2)Use the German imported precision level C1 double thread ball screw.

3)Fast displacement:820/minute,jump hole distance can reach 8-10mm.

4)Rigid soft stability and reliability.

Automatic scanning holes coodinate Parts

Features:

1)Used high-tech infrared automatic scanning brush handle hole coordinates.

2)High efficiency in changing product: 40 holes for about 5 minutes.

3)High precision positioning coordinates: tolerance +/_ 0.02 mm.

4) Easy to operate and learning, high scanning speed.

5)Less tedious steps: manual measuring pitch error precision fine tuning.

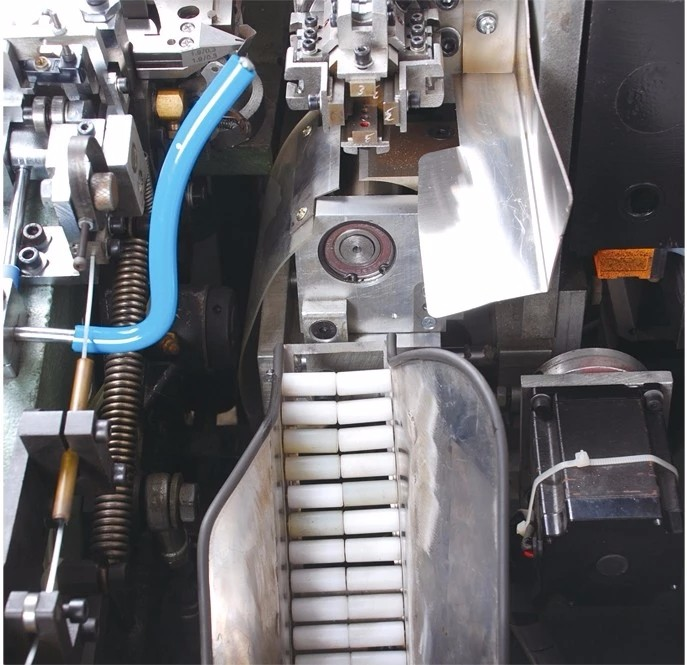

High Speed Flocking Parts

Features:

1)The introduction of German technology research and development to jig.

2)Use the German import materials plant garden, take knife , flocking pole.

3)The flocking mouth and rod through import vacuum processing high precision mirror spark technology:high hardness and good toughness, high resistance to wear.

4)Flocking machine precision machining process error value+/-0.01mm, flocking aperture:1.2 to 3.0mm.

5) Strong stability and tension, high efficiency and don't loose hair when flocking.

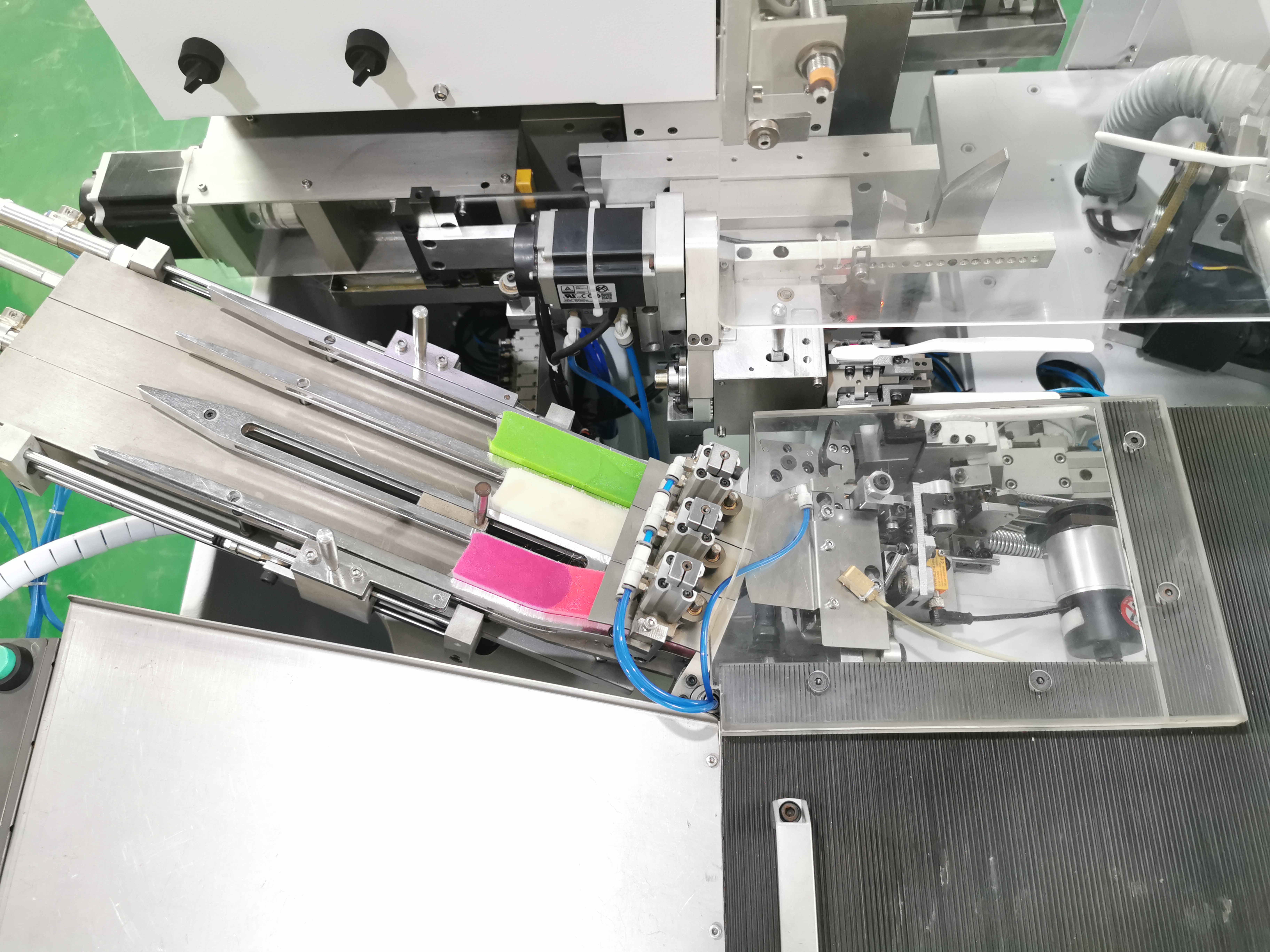

Double Color Box Parts(C2)

Features:

1)Citing Germany technology automatic cycle pressure cylinder principle: high pressure uniform and adjustable.

2)Convient adjustment adopts double dabbing cylinder hair neatly.

3)Color change the Japanese original servo motor, can support two holes in one color.

4)The electric control and wool technology, convenient operation and fast.

5)Hair knife takes hair with high stability, planting enough hair and not scatted hair.

Three Color Box Parts(C3)

Features:

1)Hair box adopts the rotation principle:German technology fission rotation reaction ability,small rigid

2)Refer to the French OGIGA role rodless cylinder pressure principle:MAO uniform pressure force,high adjustable dabbing

3)the use of three cylinder convenient adjustment hair neatly

4)Adopt Taiwan original servo motor ,high response speed can support a hole in one color

5)Adopt pneumatic and wool technology,convenient operation,quick

6)Knife take MAO high stability,and don't loose hair,not hair

Nylon Rolling handle -off Box Parts

Feature:

1)decorate device to reduce repair MAO MAO process

2)easy to brush handle landed rubber

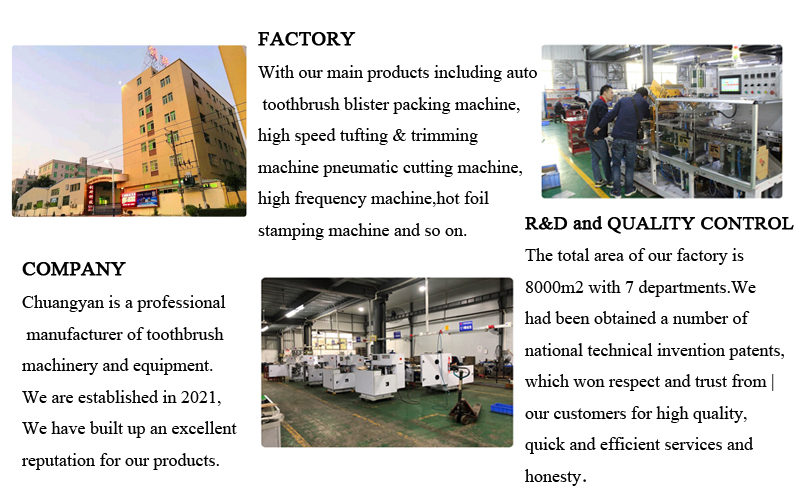

Company Introduction:

Certificate Display:

Our Partners:

Exhibition:

Packing & Delivery:

| Packaging | |

| Size | 1250(L) * 550(W) * 1250(D) (mm) |

| Weight | 175kg |

| Packaging Details | The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

FAQ: